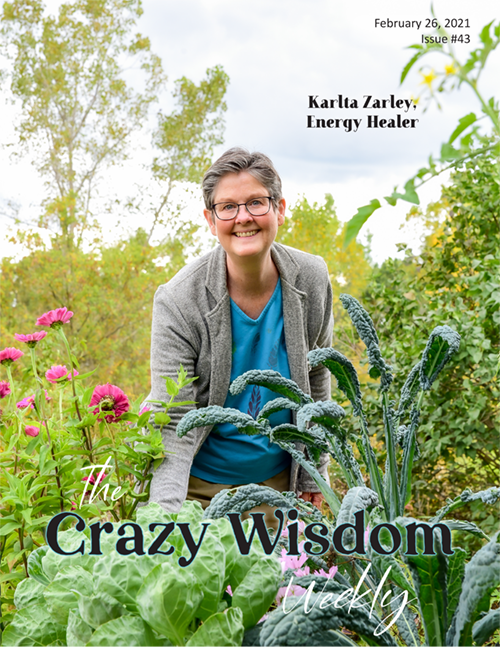

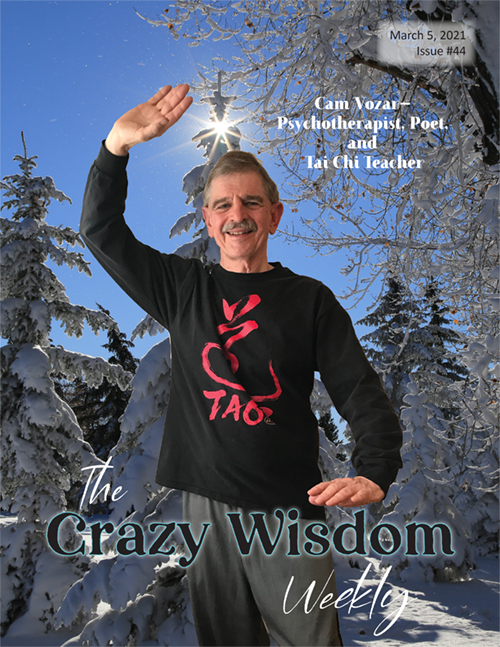

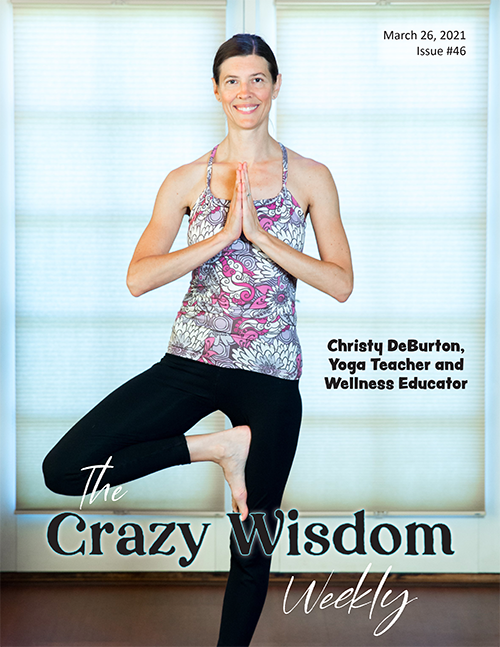

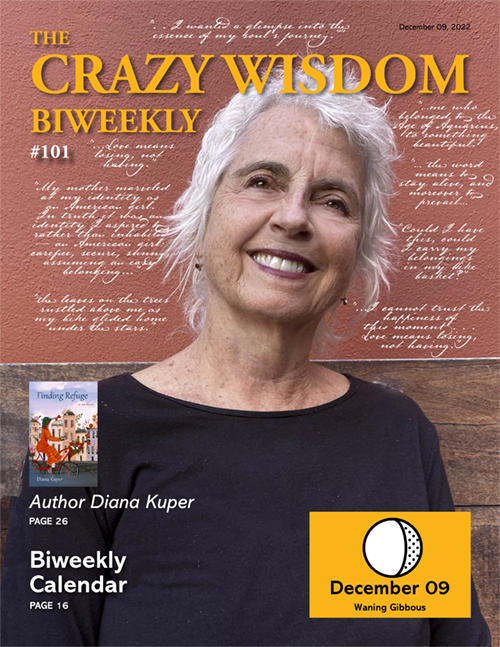

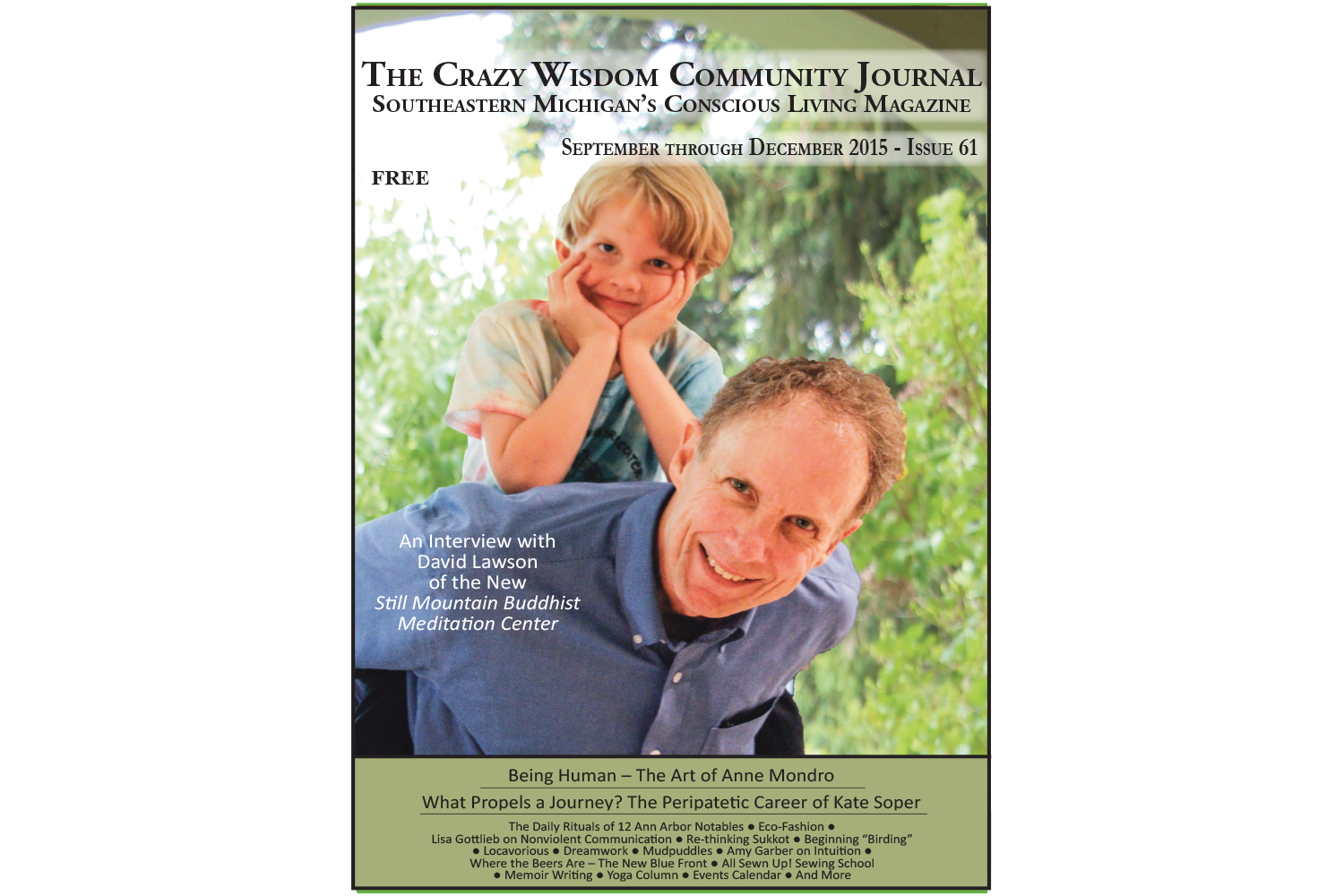

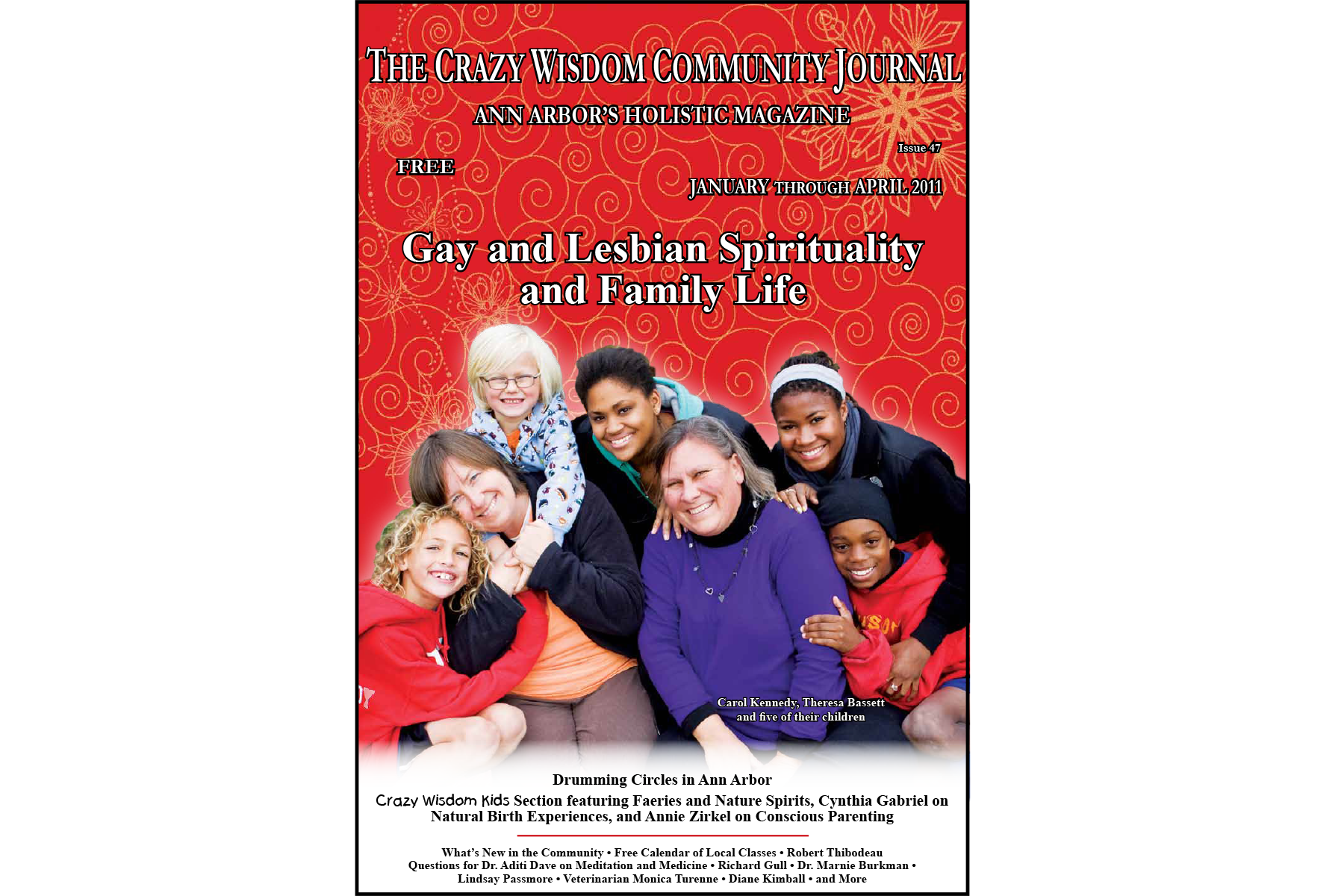

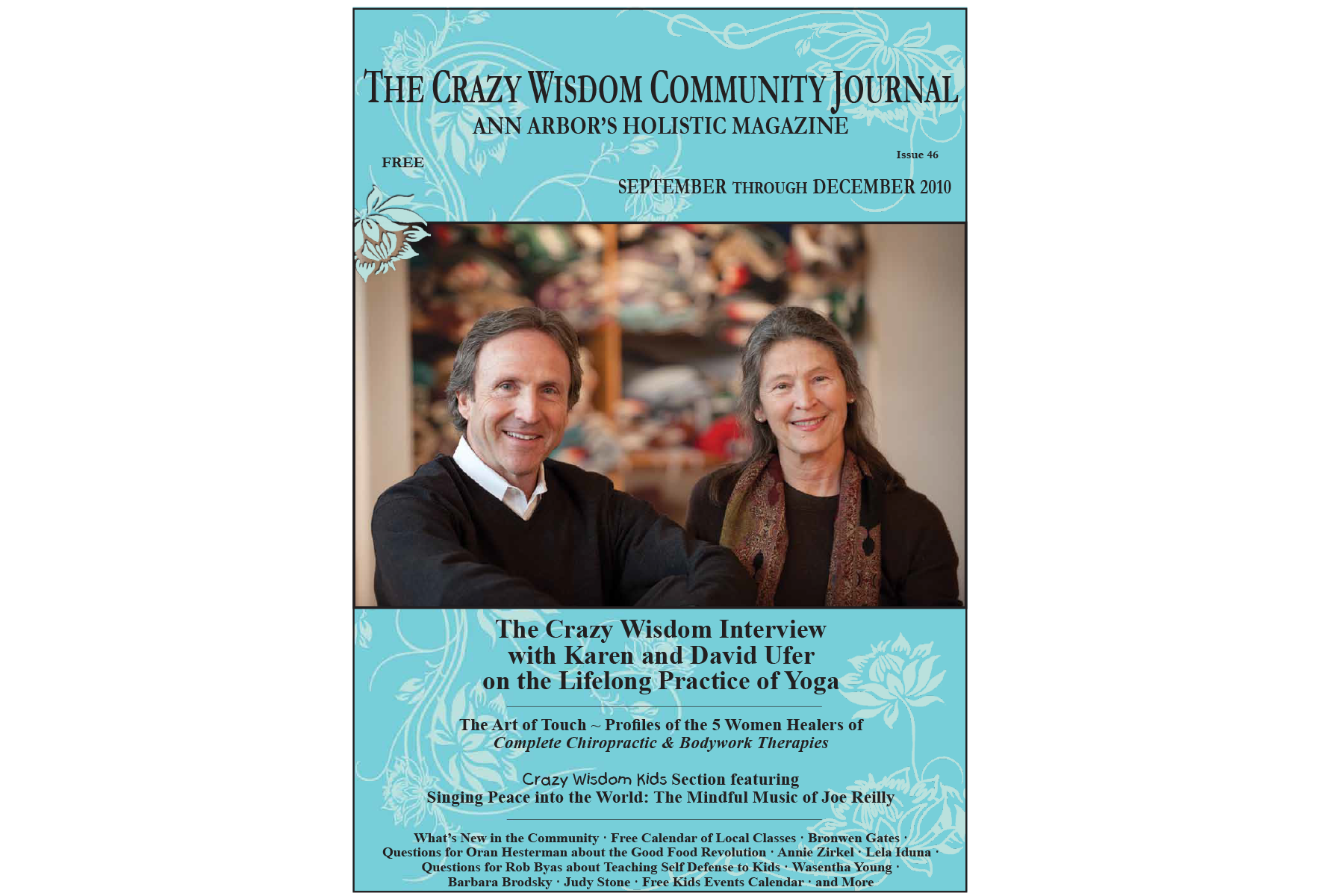

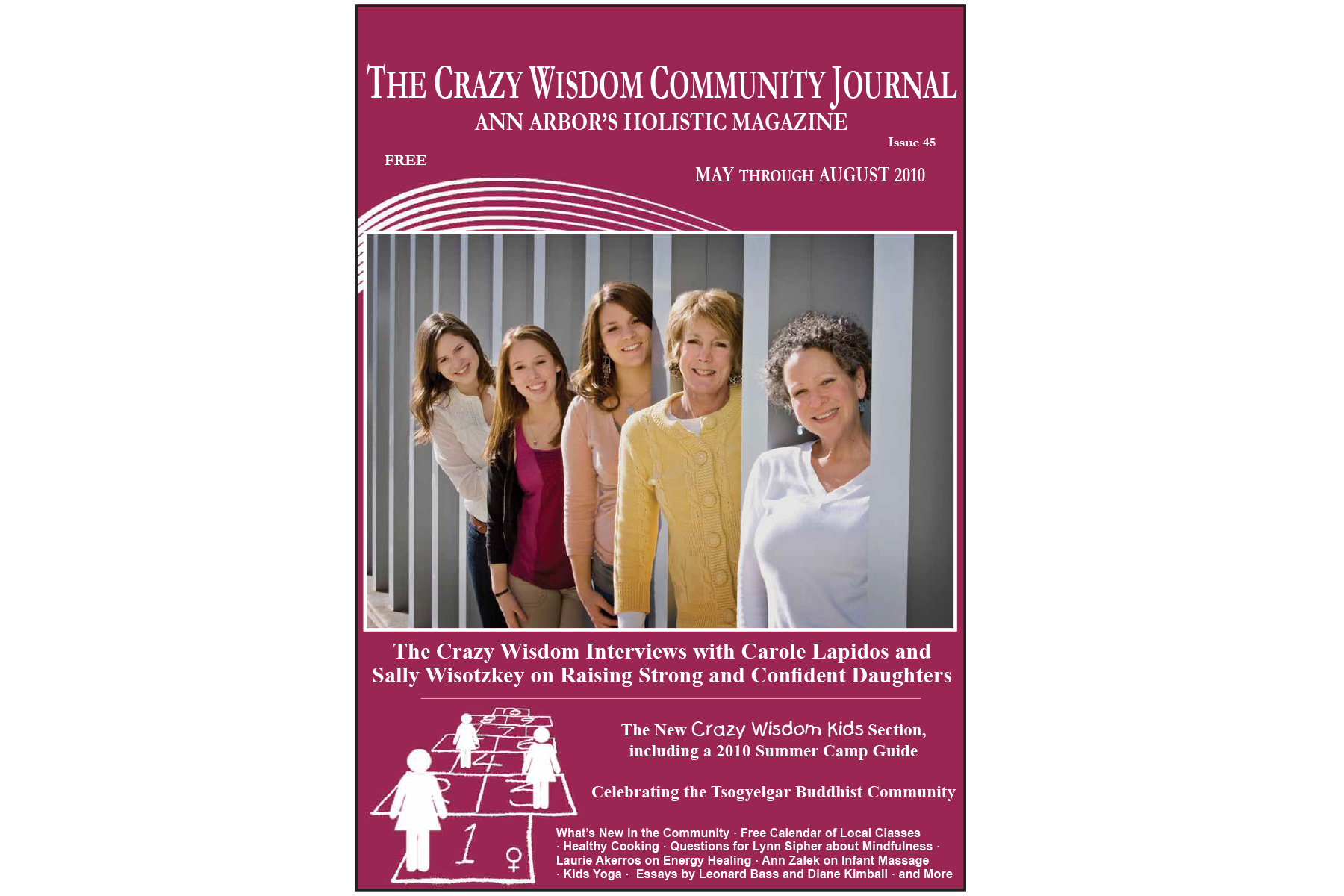

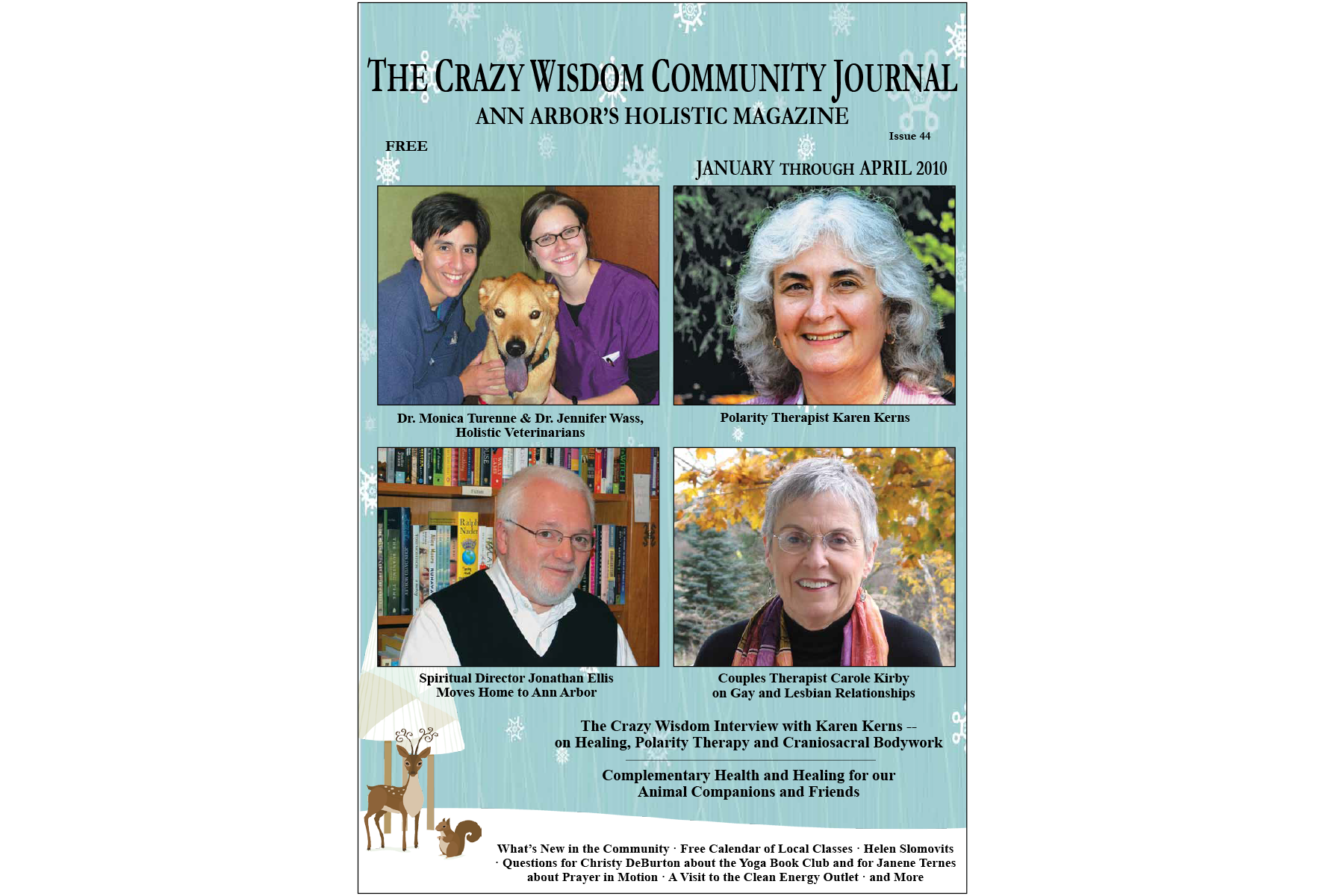

By Kirsten Mowrey • Photos by Fresh Coast Photography

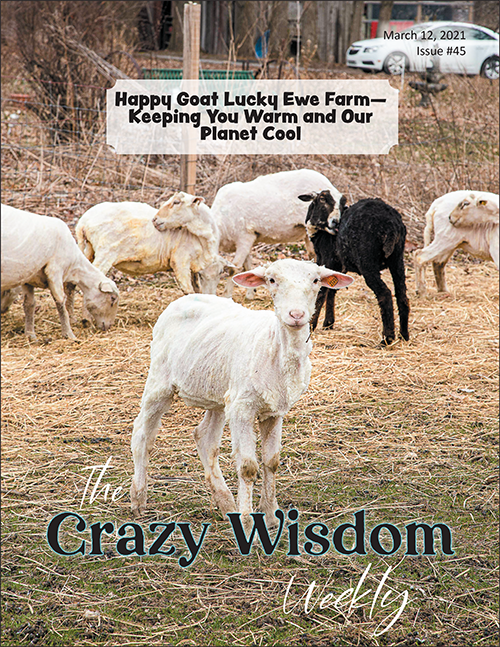

“Watch out for the ram.”

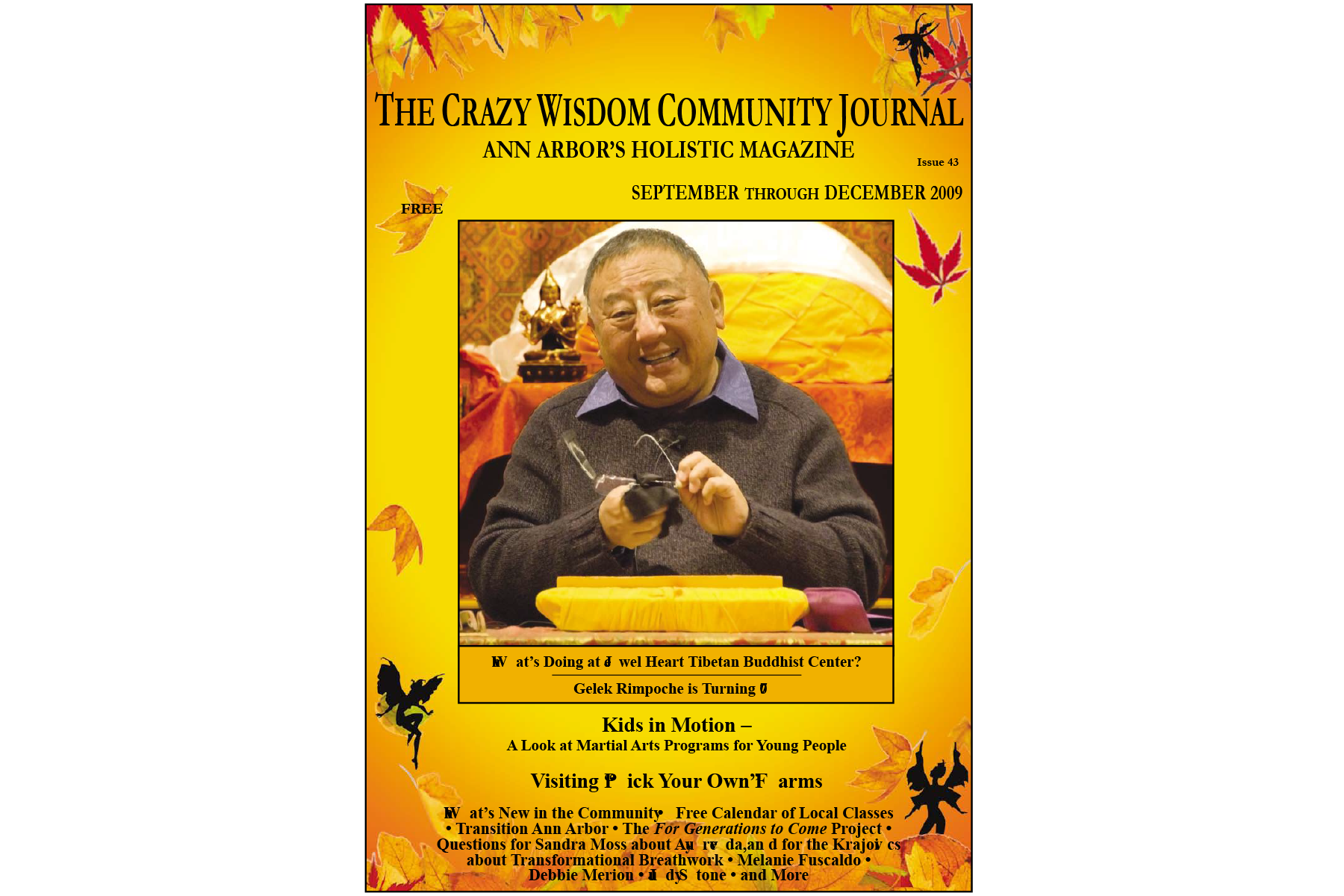

Surrounded by sheep, I turn quickly, trying to find the one ram among the twenty plus ewes in the pen. They all look alike in their thick winter fleeces on this January visit, dashing away from me when I approach like minnows in a pond. I move closer to Bridget Kavanaugh, the owner of Happy Goat Lucky Ewe farm, to make sure there isn’t enough open space for the ram to follow through on his name. Sheep bump against my thighs, and I feel like I’m being hit by toddlers with pillows, their fleeces are so thick. It’s a barnyard comedy show: I’m darting after the sheep to see how long their fleeces are, they are running away from me while chasing the hay that Kavanagh is tossing to them for their late morning feed. Finally, I spot the ram, fortunately across the pen from me, horns hidden by fleece, leaving the black straps of his chest harness the sole identifier.

He’s wearing a harness because now is when he will cover (mate) with the ewes. The harness contains orange chalk that he will leave on the rumps of the females and Kavanaugh will know who will be expecting later in the spring. He is essential to the continued future of Kavanaugh’s business, Michigan Merinos—ground zero for fiber production in Michigan.

Humans use many materials for our clothing needs. Originally, most clothing was from animal fur and skin. As human culture and agriculture developed, plant-based fibers also appeared. Plant and animal based fabrics have been the foundation for all clothing throughout history, until the advent of synthetic petroleum based fibers in the late 1800s. Increases in the environmental impact of petroleum extraction, personal attention to health, and awareness of local economies brought the question, “Why are we wearing oil?” to the forefront. Just as farmers, health professionals, and economists shone attention onto the how, where, and way of food production, dyers, fiber artists, and clothing designers are asking the same of our textiles. Our skin is the first layer of protection for our body, keeping what we don’t want out (viruses, toxic chemicals, thorns) and keeping our internal organs, bones, and other systems safe. Why would you care for your body and then place a carcinogenic chemical-soaked cloth on it for eight or more hours a day? Yet, in our anonymous long production chain economy, we do exactly that.

Knowing where your clothes come from and how they are made isn’t only about knowing what you put on your skin, it’s also about being present in your place on this planet. Every ecosystem produces fibers that help protect thin human skin. Local sourcing of fiber grounds local economies in their unique ecosystem, its strengths and limitations, helping us to come home to our place on this beautiful blue-green planet. I’ve written about growing local color via indigo dyeing, (see the article True Colors: Growing and Creating Local Color with Colorwheel in Issue #73), and creating clothing by learning to sew fabric and knit yarn, but the basis for all of our clothing is agriculture. Cotton, America’s favorite fiber, is frost intolerant and cannot be grown in Michigan. Flax, the basis for linen, grows well in Michigan’s climate but requires about seven years to become fully adapted to our ecosystem. Hemp, a strong and durable fiber, was deregulated in the national Farm Bill in 2018, but still requires significant oversight at the federal level, and other plant-based fibers are limited by our long winters.

Which leads us to animal-based fibers: wool, angora, cashmere, and alpaca. With plentiful rainfall and abundant grasses, Michigan is an excellent ecosystem for grazers. Prior to European settlement, most of southern Michigan was oak savanna and prairie, likely grazed by buffalo. European settlers arrived and substituted sheep for bison. The Saline Historical Society’s website documents local “breeders and feeders,” a 1910 newspaper article citing the sheep practices of area farmers, breeding for wool or meat, and the financial advantages of each strategy. Currently, most of the lower peninsula is defined as “open land” by the US Forest Service and so ready, again, for grazing. Kavanagh’s farm is bringing back historical practices, raising sheep and angora goats, while dedicating land to pollinators and wildlife.

She didn’t start out this way. Kavanagh was working as a legislative assistant in the Michigan state legislature when she was asked by state representative Bob Bender to become the public relations manager for the state’s bovine tuberculosis program. She said, “I was a farmer-ette back then. We had a small farm and pets for the kids, goats, horses, everything but cows.” After two years in public relations, she became the program’s interagency coordinator, working with the DNR, Agriculture, Public Health, MSU Extension, Farm Bureau, and the USDA. Then Agriculture hired her to continue that coordination position as well as being the zoetic disease health liaison between departments. Kavanagh noted “[Because] avian influenza was happening, and the same groups of people had to rise for that occasion. And we did a lot of emergency exercises for SARS and other zoonotic diseases, which are diseases that jump between humans and animals. It’s constant [work] and it's still going on, but I did it for close to twenty years.” [Covid-19 is a zoetic disease].

Kavanagh retired in 2015 and purchased her Merino sheep in 2017. She had raised sheep for meat before, but then “I discovered Merino—the wool is so absolutely amazing. Its 3000 years of research and development has gone into making the Merino sheep the perfect fiber animal. And you get the great attitude and personality of sheep. They're the most amazing animals. They're mellow, quiet, not aggressive. They just really like to eat, and ruminate, and they seem very wise to me.” Merino wool is very fine, its thickness measured in microns. Merino thickness is less than 24 microns, compared to 25 to 35 for Shetland wool. Fine wool means it feels softer to human skin and fetches a higher price.

Raw fiber needs to be processed: washed, skirted, vegetable matter removed, picked, carded, and hacked to create a base material that can then be turned into thread. Wool is processed into one of three forms: batts, roving, or yarn. Batts are large squares, typically used in quilts or for creating felted cloth, while roving is fluffy lightweight pillows of fiber ready for spinning. While Kavanagh has some clients who buy raw fleeces, and do the work themselves, for others she sends her wool off to mills for processing. Michigan, with its manufacturing and agricultural past, is fortunate to have mills within the state, keeping shipping minimal, but wool producers in other states often have to ship their wool thousands of miles. Some customers want roving, others yarn, and yarn type depends on what they create.

Kavanagh explained: “For hand knitting yarn, a soft, beautiful, light and airy twist, I use Stonehedge Fiber Mill [located in East Jordan, MI]. Hoof to Hangar in Richmond does a very nice job, too. Zeilinger’s [in Frankenmuth, one of the largest mills in the country] does the yarn for machine knitting because their twist has to be extra tight. If you look at the yarn from Zeilinger and the yarn from Stonehedge, you wouldn't believe it came from the same animal because [the one] is so super tightly spun. But the fibers open up as you wear them. So, you get your hat back or your socks and it seems kind of coarse and you think: I don't like this. I don't think this is Merino. As you wear it and wash it, it softens up and blooms into this really lovely soft yarn. But it takes a while, and the tight spin will help it last a longer amount of time.”

In the pen, I try to part the sheep’s fleeces to see the skin and measure how long it is. Dirty gray on the outside, the slightly oily (from lanolin, which the sheep secrete) parted fleece reveals whiteish fiber turning to honey colored near the skin, almost like an egg. My inspection finished, we watched the sheep leave the pen, while Kavanagh talked about sheep care, farm grants, and her upcoming shearing day. Watching the sheep walk away, I feel a calmness that the presence of animals brings. Yet, these sheep are doing more than easing my nervous system, they are also helping to combat one of the hottest topics in politics: climate change.

Carbon is an element, number six on the periodic table that hung in all chemistry labs as I was growing up. We are made of carbon, it’s in all our cells, and when we, and everything on this planet, dies, that carbon is freed up to continue moving through the many cycles that keep our planet supporting life. The carbon cycle, which includes carbon dioxide, is the name of how carbon moves through our biosphere. A very simple description looks like this: we breathe in oxygen, and we exhale carbon dioxide. Trees inhale carbon dioxide and exhale oxygen. Some processes, such as burning fossil fuel, emit large amounts of carbon dioxide. Other systems, such as oceans and atmosphere, take in carbon dioxide. Again, this is a simple description of a very complex system, but the devil, as always, is in the details.

Herbivores are often cited as a form of emissions, similar to factories and transportation, but not all herbivore activities are equal. A CAFO (concentrated animal feeding operation), where cattle are fed imported grain, kept in small lots, and slaughtered young, yields great amounts of carbon emissions and manure. Yet this is not how cattle, or any other herbivore, lives in an ecosystem. In an ecosystem, herbivores range, moving from place to place to find food and leaving behind their manure. Their grazing stimulates plant growth, causing the grasses to take in more carbon, acting as a carbon sink, not an emitter. Their manure returns nutrients to the soil, enabling more plant growth and more soil bacteria, again acting as a carbon sink. Concentrating animals is essentially creating a factory with biological components. In an ecosystem unmanaged by humans, concentrations such as these occur only seasonally and only for short periods—think of bears in Alaska feeding on spawning salmon, or migrations of wildebeest in Africa. They don’t stay there for months and months, because the ecosystem can’t support that, but the short term intensity creates a situation where the plants are grazed, the soil disturbed, and then [the land] takes in more carbon to create the new growth, overall drawing down the carbon in the atmosphere.

This cycle is exactly what Kavanagh recreates on her 35-acre farm. As we crunch through the snow, she explained, “This paddock is 13 acres. I divide it into five [areas] in the summer with premier electronet fencing. It is portable, you roll it up. They get three days on one area and then they go to another area. I have 12 separate areas. The first run of the season here,” she gestures, her blond hair swinging behind her, “we'll go to the right to recover. It's over a month before you are on it again.” During that month, the grasses and soil are sucking carbon out of the atmosphere, turning her farm in Mason into a carbon sink. Part of a USDA program, Kavanaugh’s soil is tested regularly to check the carbon uptake and her “climate-beneficial” wool fetches better prices.

Read related article: True Colors: Growing and Creating Local Color with Colorwheel

March 21st, the first day of spring. Shearing day at Happy Goat Lucky Ewe. Gray skies and deep cold belie that truth, making it feel more like winter than it has for weeks. Some of the flock have already been sheared when I arrive, Cubist Picasso versions of sheep, with sharp lines and angles in their fleece, diagonals wrapping around from back to belly. I can clearly see which ewes are pregnant now, wide hips and curving bellies hidden no longer. At the back of Kavanagh’s barn, shearer Sy Caryl and his assistant clip the herd, balancing on plywood boards while they hold the sheep between their legs, bent over in a semi-squat. Their razors hang from motors above on long cords drooping to the ground. Behind a fence, a sheep is held by an assistant ready for the next shearer, one hand on their head, one on their rump. When Caryl is ready, the gate goes down, the sheep is handed through to Sy, who bends the sheep’s head to the right and spins it onto its rump, so the sheep is sitting semi upright, as if it were in a recliner, with the sheep’s hind legs between the shearer’s. Then the shearer grabs their razor, and starts moving it through the fleece, with the left hand holding the skin taut, the right holding the razor. Merino’s have wrinkly skin, increasing surface area, and thereby the size of the fleece, but this makes it very difficult for the shearer and I see the occasional nick. The sheep don’t seem to mind though; many of them close their eyes, stretch their legs, and lie back onto the shearer. They remind me of ladies at the beauty parlor—that look women get on their faces when their hair is washed: closed eyes, deep breaths, pleasure loosening their jaws. The amount of wool pooling at the feet of the shearer is stunning, clouds of pale foam up to their knees, as if another whole sheep lies there.

Sheep need to be shorn for their health. If unshorn, the wool would continue to grow until it hampered the sheep’s ability to move. Seeing the amount of wool coming off sheep after sheep, I can imagine the discomfort of moving with it on a hot summer day. The shearer keeps moving the sheep, clipping off the hair. Sometimes it's a leg, then the head, then the rump, until he has encircled the sheep and all the wool lies at his feet. Then he pushes the sheep forward onto their forelegs, away from the wool and releases it. The sheep shakes itself, then walks off on surprisingly stocky legs, back to the field where its friends browse on hay. Some give an opinionated “Baa”, as if they were giving a review for ShearAdvisor, before they, too, walk off, while the shearer takes a moment to stretch upright and loosen his back.

Lora Herron stands near me, watching sheep MO 4242 (her ear tag number) get sheared; this fleece will be hers. Tall, blonde, and fit looking, Herron lives in Grand Blanc and visited the farm a few weeks earlier to choose her fleece. It’s a doozy, one of the largest, and Herron laughs, delighted by plans of spinning and knitting with it. Once the fleece is off the sheep, Kavanagh bundles it into a garbage bag, keeping it away from the mud, then moves back into the barn to a large plastic table at the opposite end. Here she spreads out the fleece for skirting, where tarry brown lanolin clotted ends, vegetable matter and other bits of unusable wool get removed from the fleece. Kavanagh holds up the lace-like fleece up to the light, spreading it wide while teaching Herron about her new acquisition. Once skirted, the fleece goes back in the bag and the two women head up to Kavanagh’s house to weigh the fleece and complete the sale. Herron will need to wash and card the fleece to make it ready to spin, and the eagerness in her face shows that is no chore for her.

This moment, Herron’s face shining with joy as she holds her fleece and Kavanagh’s shared joy and pride—this is the moment that all the work builds toward. This is the moment when the producer and artist meet, when Herron receives a fleece from a sheep she knows was well cared for, and Kavanagh hands her labor over to a creator who knows the value of that wool. It is beyond the transaction, it is relational, exponential beyond what currency and numbers can quantify, a way of being in the world that affirms life and nourishes spirit.

Contrast that with the commodities market. Wool as a commodity has faced flat prices for decades. “Most wool goes for 17 cents to 26 cents a pound,” said Kavanagh. “People don't even get paid for their fiber. The shearer is there to take the wool off because they need to have their wool removed. The shearer comes in and he takes it and gets a nice check because he's [collecting] from all of the farms. He might have 10,000 pounds of wool at 26 cents a pound. Merino, you get $4 a pound for the wool.”

Kavanagh, however, gets $10 a pound, selling directly to spinners and knitters, offering a high-quality product. “I don't make a lot, but I make enough to continuously improve the farm.” She also makes hats. “My goal for this year is to find a ski resort that wants to carry US grown and made hats. My hats are expensive, but everything is traced and traceable.” Current politics are also creating new options for Kavanagh. Tariffs and embargoes against China mean that yarn stores are unable to receive yarns from certain vendors or only in very limited supply. What does a shepherdess do? “I contacted two yarn store owners. I said, Hey, why don't you do a run of your own yarn for your own shop and buy local? One is buying a hundred pounds of wool. [The retail store] Why Knot Fibers up in Traverse City, is going to have their own yarn made and their own label.”

The late Macarthur Fellow and systems analyst, Donella Meadows, wrote of leverage points. Places where we can change systems to “get more of what we want and less of what is undesirable.” She identified ten places where we could do this; one of the most useful is the paradigm being used, the mind-set behind the goals and purposes. The current mind-set behind our clothing system is to create as cheaply as possible and ignore any human, environmental, or social impact as incidental, but with a small mental sidestep, we can leave that paradigm and the waste and pain of human and animal lives aside. We can move into a mindset that is healthier for us, our planet, our ecosystems, and the places we live. As Meadows wrote, “There’s nothing physical or expensive or even slow in the process of paradigm change. All it takes is a click in the mind, a falling of scales from the eyes, a new way of seeing.” (Thinking in Systems p. 163-164)

Since I wrote this article, we have as a nation learned a great deal about long supply chains and how they affect us. Weeks of shortages of chemicals for coronavirus testing, limited PPE (personal protection equipment) for hospital and health care workers because of textile mills thousands of miles away, empty shelves with no hand sanitizer. Local resources helped us to meet some of these needs: quilters organized via Maker-works and created cloth masks to fill the gap, Operation Face Shield used 3-D printers to create necessary equipment, and distillers changed from beverages to hand sanitizer. These local industries and supply chains were there because people like Bridget Kavanagh and others believed in creating locally to meet local needs. Corporations may source distantly and cheaply, but if there is a lesson to take from our coronavirus shutdown, it is to show the fallacy of those distant sources, the faults in that paradigm, and the strengths of a strong local economy. I hope you have enjoyed these articles about natural dyes, knitting, local jeans, and local wool. I hope they sparked interest in how we color, create, and source our clothing, and invited thoughtful introspection about your own relationship to your wardrobe, making the question, “What do I wear today?” bigger than you ever imagined.

Visit Bridget Kavanaugh’s online store at: www.michiganmerinos.com. To learn more about plant and animal- based fibers, or about creating a local textile economy, visit www.fibershed.org.

There are many ways nutrient recycling is implemented at Strawbale Studio that can be used in your home garden. You might even get together with your gardening friends and start an “idea map” of the various natural resources on your site or community garden, and in your region, and how they could be returned to the circle of life!