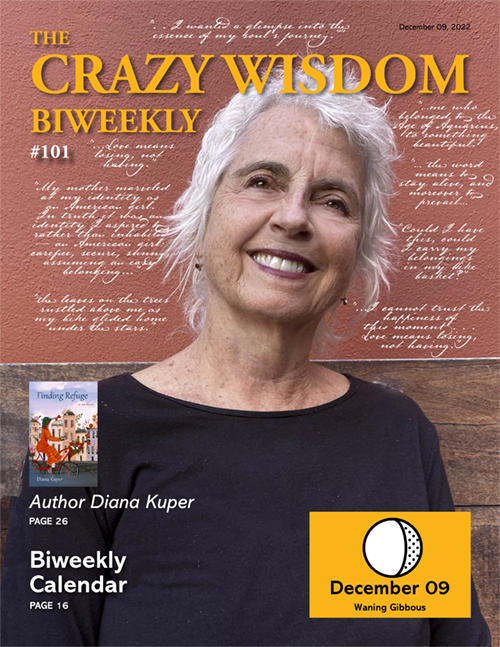

By Kirsten Mowrey

“Buy local.” It’s a phrase we’ve seen for years, encouraging us to support the mom and pop down the street, the independent bookstore, and the small retailer. Local food and the local food economy have grown in Michigan over the last decade, and the Ann Arbor Farmers Market features new farmers every year, but there are other needs and areas that could benefit from using the same lens. Clothing is one of them.

Clothing ourselves is a necessity for some and a passion for others, but however you see it, we could all benefit from asking the questions, “Where did this come from? Who made it? And how?” Fast fashion, like fast food, is not healthy, but unfortunately, it is what our clothing industry has become, and our closets are bursting from it. If you doubt this, watch an episode of “Marie Kondo” or “Tiny House Nation” to see beds piled with clothes, overstuffed dresser drawers, and relationships strained over closet space.

This article isn’t trying to guilt you into decluttering, but rather encourage you to look at what lies underneath (besides underwear). We think our clothes are cheap, yet if you look at how often you wear that “so cheap” shirt or pants, it is actually more expensive than you think—a $20 shirt worn twice costs you $10 a wear, versus a $40 shirt worn ten times, which would cost you $4 per wear. The expense isn’t only in your pocketbook, though. Textile production produces 1.2 billion tons of CO2 per year, contributing to global warming. If your shirt is made with synthetic materials (like polyester), it sheds every time you wash it, creating micro-plastic lint that will eventually show up in your drinking water and your body.

For example, take the T-shirt I recently purchased: 50% polyester (plastic), 25% cotton, 25% rayon (wood pulp—contributing to deforestation and processed with the known toxins carbon disulfide and sulfuric acid) and made in Nicaragua. Who picked the cotton, wove the fabric, or sewed the seams? Twenty-one million people are engaged in forced labor, and 55% of those are women, as reported by the U.S. Department of Labor. According to the 2019 Fashion Transparency Index, a rating of 200 global producers including Adidas, Patagonia, and H&M, only five companies scored above 60% on issues of transparency of labor and environmental impacts in their supply chain, and no company scored greater than 70%.

With these kinds of statistics, local clothing makes sense. Going local implicitly contains the ability of the consumer to know more about the company. Local is not a simple remedy, but rather a step toward accountability, responsibility, and knowledge about who, where, and how the clothes we wear are made, how workers are treated, and what by-products are created. In addition, local adds to our economic diversity and tax base, creating a stable community. When I looked for locally produced clothing, the first place I decided to start was with a raw material: wool fiber at SPUN.

Carol and Pete Sickman-Garner opened SPUN three years ago on the south side of Kerrytown overlooking the Ann Arbor Farmers Market. Before that Carol was an editor and Pete was at Zingerman’s. They wanted something different, something they could do together. After talking with the Brinkerhoff’s (owners of the Argus Farm Stop), digging in and doing research, and finding that there was no fiber store in town, they opened their doors.

When I asked Carol and Pete about local sourcing, it was immediately clear this is not a straightforward answer. “Fleece to needle is the way people talk about it,” said Carol. “We have a fair amount of yarn in the shop that can be traced back to the ranch and through every step of the production process. It’s all manufactured here in the U.S.A. Some of it is at a pretty low price range, some mid-range, and some of it’s quite high.” Not everything in the shop meets this standard because the Sickman-Garners wanted to meet the needs of as many customers as possible. “We’ve always wanted to make sure that we think about inclusivity in a lot of ways like age and gender,” said Carol. “We also think about economic inclusivity, and we want the shop to be a place where we can set people up with yarn at their price point.”

Pete brought up another aspect when he mentioned hand-dyed yarn. “We love the yarn they’re using to dye, but we can’t necessarily say exactly where it came from.” Yet, they find value in supporting what are often small, women-owned businesses. They also sell small wooden tags that say “Made in Michigan” that can be sewn onto garments to identify “that it was handmade, that it had a source and location,” said Pete. He added, “I don’t think I appreciated enough how much went into all the things Carol knit for me, Lily, and Robin (the Sickman-Garners’ daughters) over the years until I started working here.”

Read a Related Article: The Eco-Friendly Wardrobe

The Sickman-Garners’ commitment to making wool, and all the objects one can make with it, accessible to all is evident in the shop. Carol mentioned a movement within the fiber community toward inclusivity of all people, and in support of that SPUN features patterns, hand-dyers, and samples from designers who don’t fit the white middle-aged female stereotype. Several male knitters visit the shop, and Pete, who is learning to knit, admires a fellow male staff member he calls “extremely talented.” Making things also creates a community, because of the time involved, so SPUN has a seating area where knitters and those who crochet can sit, chat, and enjoy being together. “Making something and giving it to someone,” Carol said, “feels different from buying something and giving it.”

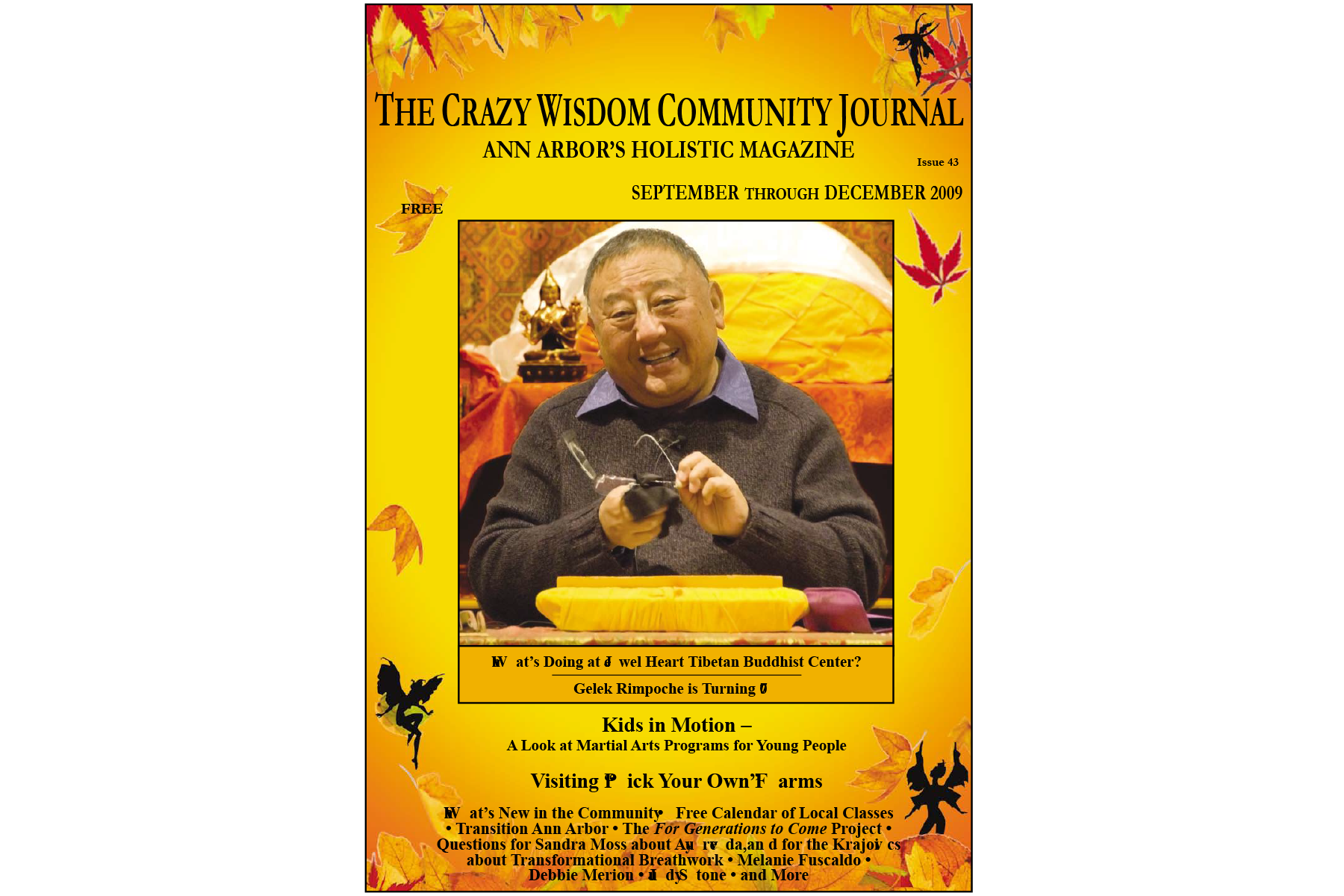

Visit Jewelheart.org for more information!

While knitting allows one outlet for responsibly sourcing your clothing, sewing allows another. Tooya Ritchey is an Ann Arbor native who returned home after years in the fashion industry in New York. In 1999, she and her husband, Leif, moved to New York City and connected with other artists. They began experimenting with clothing, using natural colors and untreated materials, adding handwork, and sewing individual pieces. If you remember fashion at the turn of the century, such details, now ubiquitous, were unheard of. They joined Johanna Hofring at the Art Fiend Foundation on the lower east side, which Ritchey described as “a very Swedish aesthetic. The floor was unfinished wood and we had a tree branch hung with clothes. We received a lot of press. It was a really fun, inspiring time, and you could just make something and hang it up [for sale].” Eventually buyers came to the store, leading the couple to create seasonal lines, then a showroom, and increase production. Production as two people proved a challenge, however, and Leif and Tooya followed their creativity to other fields: Leif to painting and Ritchey to producing fashion shows and working for Yohji Yamamoto.

The birth of her son, Theo, caused Ritchey to return to making and creating clothing. “I really liked the feeling of making clothes for him. It was really satisfying to get so tiny. [With] a T-shirt, you can make ten out of a yard, and it costs a 10th [of retail]. I like them to be comfortable and organic.” As Theo grew older, organic clothing in his size was still available, but Ritchey said, “I got so much joy out of making things and being able to make them exactly to my own specifications.” Ritchey also made small animals out of the scraps, and these are the focus of her online shop, rosietooya.com. She also met Amanda Cinco-Hoyt, one of the founders of Colorwheel (see the article in The Crazy Wisdom Community Journal Issue #73), and connected with local textile makers. Organics have long been a priority for Tooya, and most of those textiles come from overseas. Not all producers have a transparent supply chain, so Ritchey found herself attracted to “this person actually made this cloth, or they’ve spun this yarn, and then I’m using it” as part of her greater world view. “The more I get into it, the further I want to go. When I’m using things that are [transparent], I can feel more relaxed because I know that no one along the line has been injured in any way.”

Ritchey continued her thinking, “How can you live lightly on the earth? I was thinking about sustainability. What is it to really be sustainable, and is sustainable enough, or do we have to be more like regenerative? Sustainable is a good starting point to stop doing lots of damage. But I think a lot of sustainable is just trying to do less damage. To me, it’s how can you do no damage and then how can you do good? How can what you’re doing actually leave more beauty, or be better for having been farmed, or better for having been made?”

This exact question is the premise behind Fibershed, an experiment expanded into reality. Founder Rebecca Burgess decided to source her clothing for one year from her local community in northern California. Burgess, a dyer and fiber artist, discovered vast gaps that led her to creating Fibershed, now a non-profit with affiliates around the country, including the Great Lakes. A fibershed, like a foodshed or a watershed, describes a particular geographic area from which a community sources its needs; in this case, clothing. The vision is bold: to create economic, environmental, and community prosperity around the production and creation of textiles. To educate their audience, Fibershed produces a PDF download “Clothing Guide: A Menu of Actions and Options” to guide consumers to learn, think, and purchase from companies that are using some of their methods and principles. Included in that list are three Michigan-based companies: Conscious Clothing in Belmont, Detroit Denim in Detroit, and Maggie’s Organics in Dexter.

Scarves from Conscious Clothing.

Conscious Clothing takes a more (historically) traditional approach. On their website each item has measurements for the garment offered. For example, the very cute Revolution Dress size XS measures Bust 35 / Hip 40.5 / Sleeve Length 12.5 / Length 36. Measurements are given for each size up to XL. You can customize the item for an additional $20 fee. Once you place your order, your item will ship in two to three weeks, a model that was followed by seamstresses and tailors in the 1800s. Their FAQ page informs about their fabric choices and gives a brief tutorial about the fibers used, dyes, and sourcing. Maggie’s Organics goes further, offering “Behind the Label” tabs on every item that they create, listing NGOs, mill names, their third party verification companies, and even information on transparency and credibility. Conscious Clothing lists shops that carry their products, while Maggie’s can be found in major retailers such as Whole Foods.

Detroit Denim, founded in 2010, has a storefront and factory in the Riverfront Warehouse District on Detroit’s lower east side, not far from Belle Isle. When I spoke with founder Eric Yelsma, he told me the company employs ten people and is vertically integrated, meaning they design the patterns, manufacture the items, and sell their own brand. In following this model, Detroit Denim is acting more like an haute couture house than a modern retailer. Contrast that with what Yelsma calls “contract manufacturing,” also known as “outsourcing,” the typical model in clothing manufacturing. Outsourcing decreases costs, but also decreases control of quality and process, creating the obfuscating system the textile industry currently uses. According to a video on their website, all materials are domestically sourced, and Yelsma acknowledges that “there’s a premium to that.” Which explains the $215 price tag.

However, part of changing the model means changing the way we evaluate our clothes. Using the idea of “price per wear,” let’s look at those $215 Detroit Denim jeans. If you purchase a pair of jeans that you wear twice a week for five years, your cost is less than two dollars per wear. I asked Yelsma if he had ever worn out a pair of jeans. “Heck yeah,” he replied. “I wear them every day, so I go through a pair in a year. They are 100% cotton and will wear out.” His price per wear (given 365 days of wear) is 60 cents. Given that 60% of all clothing is discarded within the same year, these jeans saved you money, shopping time, transportation costs, provided fair labor, and reduced your carbon and ecological footprint.

Clothing made in this way does have a high dollar cost, not because of branding or marketing, but because of manufacturing: water usage, dye impact, and labor are all accommodated for in the price of the garment, not hidden or displaced. We pay for water treatment for our drinking water because we dump waste in it; we pay for landfills because we dispose of items that are broken, non-recyclable, or no longer cared for, we pay for government to monitor air quality. Transparent supply chains that allowed consumers to think about the bigger impact of their purchases could possibly reduce all of those costs. Yet economically, locally sourced clothing isn’t feasible for everyone. But as models switch over and economies of scale come into play, costs change.

Finally, there is the question of human trafficking. Around the globe, women and children are forced to work in textile manufacturing and agriculture. According to End Slavery Now, 1.4 million Uzbek children are forced to pick cotton for clothing. More children are indentured to textile manufacturing than the number of children enrolled in the New York public school system. End Slavery Now offers an online calculator to find out your slavery footprint and offers actions individuals and businesses can take to help end slavery.

In the face of all these conundrums, Ritchey said, “It’s overwhelming. I feel overwhelmed sometimes when I’m trying to buy organically and then you hear there’s this whole thing you’d hadn’t even considered. Or we’re going to use organic cotton. A really good thing, right? But it takes too much water. Where do you even begin? That’s why I’m saying just begin somewhere, do what you can, get inspired, and have fun thinking of ways to be zero waste.”

All of these individuals and businesses are, as Yelsma said in the video, “trying to create a new apparel model that’s not so gross.” And there are more benefits possible than cleaner air, water, and fair labor. As SPUN’s Carol Sickman-Garner said, “Another benefit of knitting is learning to accept the imperfections in life. Because you make mistakes and it’s not the end of the world. You can fix some, or you can adapt accordingly.” In our current whirlwind of culture change, the ability to adapt may be the greatest benefit of all.

For information on global producers see www.fashionrevolution.org/resources and click on Fashion Transparency Index. For Fibershed’s clothing guide, go to www.fibershed.com/programs and click on Education.

SPUN is located in Kerrytown on the second floor, 407 N. 5th Avenue, Ann Arbor.

Detroit Denim is located at 2987 Franklin St, Suite B Detroit, MI 48207.

Visit Conscious Clothing and Maggie’s Organics online at consciousclothing.net, and maggiesorganics.com.

January is National Slavery and Human Trafficking Prevention month. For information on modern slavery, visit www.ilo.org and click on the pdf, “Global Estimates of Modern Slavery.” To calculate your slavery footprint, visit www.endslaverynow.org.

Related Content:

It’s the perfect time to preserve the abundance of the local harvest—and make meal prep a snap all through the winter! If you’ve only used your dehydrator to make apple rings and kale chips, get ready to fall in love with dehydrating some new vegetables and learn how to use them to make fast, nutritious meals.